Big Brake Service

Big Brake Service

I have a 1995 BMW 540i Sport with a Dinan Stage 3 brake kit installed. When I needed new pads and rotors I called Dinan to purchase replacements. I was shocked to learn how expensive they are and wondered it there was a cheaper way. After a bit or research I learned the the Dinan kit is in fact a complete brake system of mighty euro-only 1995 M5. I ordered a set of front rotors, a wear sensor, and a set of pads for a 1995 M5 from Pacific BMW. Service was excellent as usual and the parts arrived in just over a week.

A couple of people warned me that Dinan may modify the hubs for his kit in such a way as to make the factory rotors not fit. This is not the case, the factory parts fit perfectly.

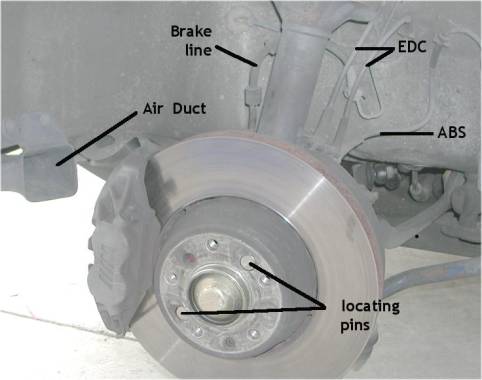

Here is the old rotor prior to removal. Note the air duct to provide cool air from the front of the car. It seems to point mostly at the tire, but any increased airflow in this location is good. In this pic you can also see the two connections to the EDC shocks and the ABS sensor.

M5 Rotors have two locating pins in the hub; these in conjunction with the lug bolts hold the rotor to the car. The retaining screw visible at 6 o clock on the rotor face is not structural and simply keeps the rotors on while changing wheels or brake calipers.

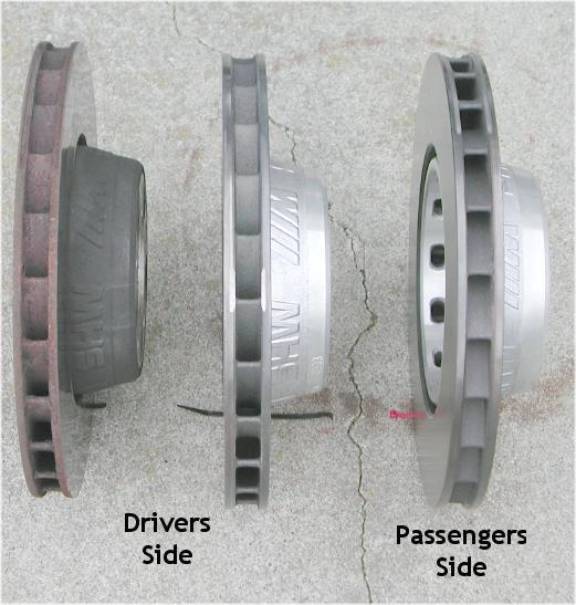

Here is an old rotor with both new rotors showing the direction of the cooling vanes used to increase airflow through the rotor. The aluminium hub is used to save weigh and is vented to allow air to the center of the rotor. The two piece design is commonly seen in racing applications but is rare in production cars and rarer still in car imported to the US. Evolution versions of the European M3s use a smaller version of this same design, but all US spec cars came with fixed rotors for concerns about liability should a two piece rotor come apart. Many performance oriented M3 owners upgrade to the Euro rotors and they are pretty much mandatory at open track events.

In this backside close-up you can see the vented aluminum center hat, floating pins, and rotor surface with machining marks. The stainless steel pins allow the rotor to float as it expands and contracts with heating and cooling.

Another close-up of the rotor showing the locating pins and ///M logo on the center hat. The air gap allows the rotor to get very hot during sustained heavy braking yet transfer little heat to the hub and wheel bearings.

Above is the four-piston caliper as removed. You can see the crossover tube that carries fluid from the inner pair of pistons to the outer. The pistons are almost fully extended due to thin (29.7mm) rotors and thin pads. It is easier to push the pistons back into the calipers before removing them. I used a small screwdriver like pry-bar from Snap-on to spread the pads while releasing the bleed-screw. If you wait to do it until after they are off the car as shown in the picture you will need to devise a way of bushing back all four pistons at once because if you push on one, the other three extend. I ended up putting the caliper back on the car to push those pads back. A keen observer will see the small stainless steel rings built into the piston seal. They appear to be a heat and debris shield for the seal very cool.

Yes, I used a milk-crate to hold the caliper please don t call the milk crate police. I have a favorite bent coat hanger that I have always used to hang the caliper from the spring. I ve used it dozens of times works like a charm. Not this big dog. No coat hanger I have ever seen will hold this caliper.

Replacing pads is easy with racing style pad retainers. A pair of pins on the back of the caliper holds the pads in. A small drift pin is used to drive the pins out and once past the first pad, you may be able to push the pin out by hand. In the photo below the pins go through the hole on the top of the pad. Once the pins are out the pads can be removed using pliers. You did retract the pistons prior to removing the pads didn t you?

To replace rotors you will then need to remove the caliper, which is held on by two 17mm bolts. Once the caliper has been removed, the rotor-retaining bolt is removed be careful that very heavy rotor is likely to come off with it.

Notice that there are no adopters or spacers of any kind this is a completely bolt on fitment for 540i Sport owners. I believe regular 540 and maybe even 52X and 53X owners can also upgrade but will need to use 1995 US 540i Sport front hubs.

In this close-up of the pad you can see the additional material on the back of the pad. It has a plasticy feel and may be a heat insulator or vibration damper or both. It has the same thickness at the thin steel plates I found between the pad and the pistons when I removed them. The backs of the original pads were smooth painted steel. I did not reuse the steel plates

Here is the new rotor and the caliper with new pads installed. I used a small wire wheel to cleanup the caliper removing as much old brake dust and gunk as possible. Wear a dust mask if you do this! The copper colored spots are Wurth CU8000 a anti-seize product heat resistant to over 1400F. I use it in small amounts whereever the pads touch the caliper and on the pad mounting pins. You can also see it between the rotor and the hub.

All done torque those to 90 Ft-Lbs and go. I probably should have cleaned up the wheels while they were off .

Nawww